Tub Casting: Tub resurfacing’s cooler, younger brother

There are a few options for total tub refurbishment on the market. (All of which we have been identified in our blog: “Tub Reglazing vs Tub Replacement: Which Is Right For You?” if you’d like to read more about all the options at your disposal.) To briefly summarize, these options range from full replacement, liners, to refinishing, and now the latest development: casting. But casting and resurfacing are the only options in the bunch that do not involve the installation of new items or the ripping out of old. And they both essentially achieve the same goal in the same way: updating the tub in a short amount of time, on a tight budget, with minimal amounts of effort on the part of the homeowner. But as much as these two services appear to share some similarities, interestingly enough, it is their differences that really highlight the benefits and shortcomings of each service. Before jumping in with both feet, let’s lay out some fundamental info for both tub resurfacing and tub casting.

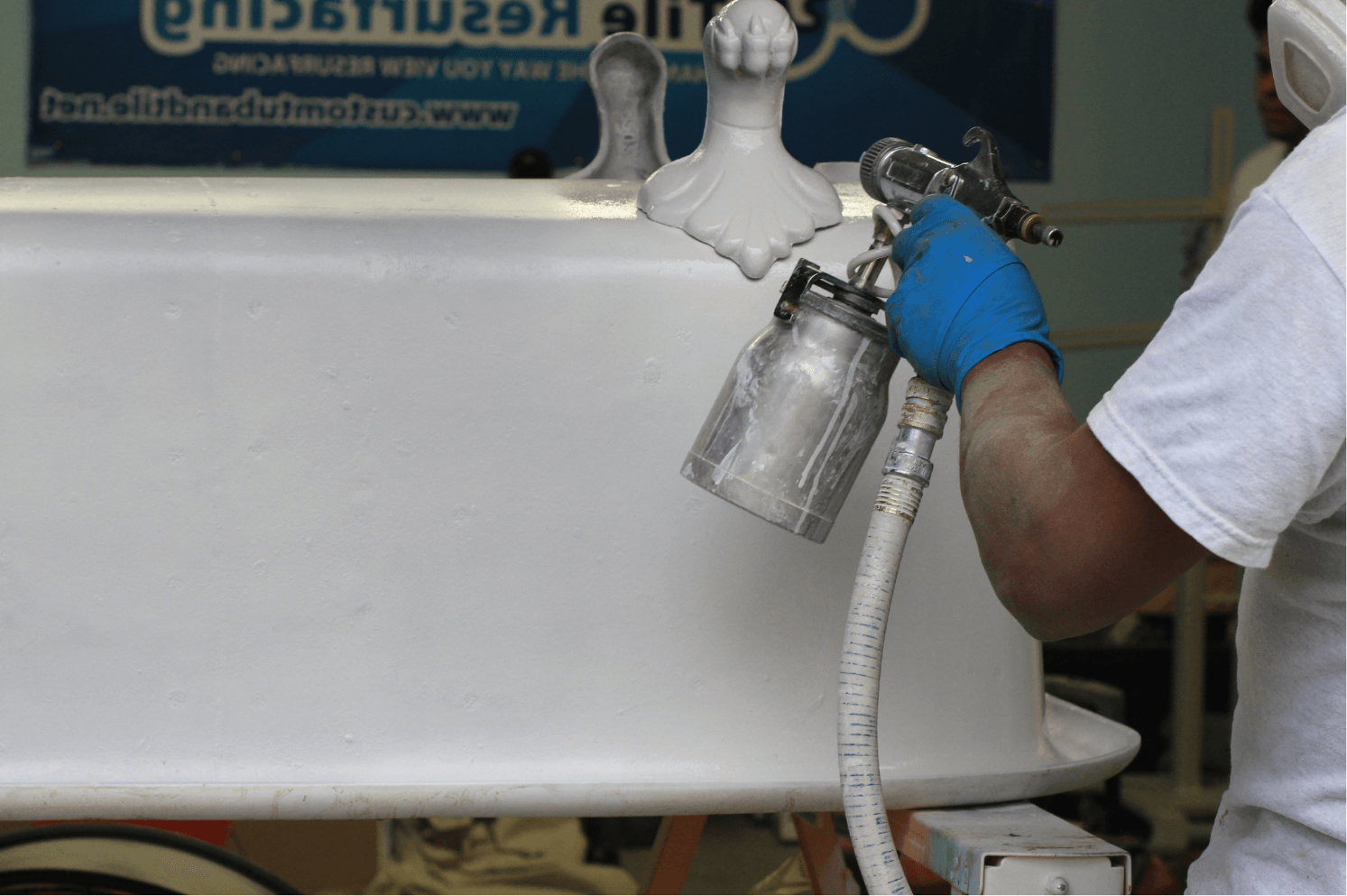

Tub resurfacing has been around for a while and is probably one of the oldest methods of refurbishment in terms of your bathroom. In order to achieve a glossy or like-new finish the bathroom is essentially turned into a paint booth. And the coating is sprayed onto the tub or other surface, similar to the way paint is applied to cars. Homeowners often choose this particular service for a few reasons, the most common being: a tight remodeling budget, preparing their home for sale, or sprucing up a rental unit between tenants. And because resurfacing is versatile enough to be applied to multiple areas (i.e. tubs, shower pans, tile walls, etc) it is the preferred service for people who want to tackle multiple projects.

Tub casting is fairly new to the world of tub refinishing. It achieves the same goal as resurfacing and is fairly similar in practice. With the most obvious difference being application method; the casting coating is poured onto the tub as opposed to being sprayed on. And homeowners generally choose to cast their tub for the generally the same reasons they resurface: budget, home sales, or apartment turns. However, people who have had their tub resurfaced in the past prefer casting because it is permanent and their tub will not peel, chip, or flake.

With that macro view in mind we are ready to delve into the nitty gritty of each service to break down the difference between the two…

APPLICATION

As previously mentioned, the clearest difference between tub resurfacing and tub casting is the way the material is applied. The tub resurfacing process entails a coating that is sprayed onto the tub, that application method involves a spray gun and lots of preventative prep work to eliminate overspray and other dust. Unfortunately, with this type of application it is impossible to completely prevent airborne materials like the coating, or the dust created during the prep work simply with the ventilation system used by your refinisher. It is also important to note that this particular method of application can leave some room for error if the technician is not familiar with the equipment.

Tub casting has an entirely different application method. Once properly mixed, this coating is poured onto the tub. Then gravity goes to work with a little help from the technician. The coating self-levels leaving a perfectly smooth and glossy surface which bonds permanently to the tub’s original surface. This pour application completely eliminates any airborne chemicals and the need for a ventilation system. It can be a fairly messy procedure but proper precaution taken during the masking and taping phase of the project removes all cause for alarm during clean up.

ODOR

One of the biggest pain points of traditional resurfacing is the odor associated with the process; we compare the odor to that of a nail salon. The good news is that although it is uncomfortable the odor is non toxic. But it is caused by evaporating solvents mixed into the coating that allow the finish to harden. Due to this odor traditional resurfacing requires several safety measure to protect the technician and anyone else present in the home; including but not limited to fresh air respirators and ventilation systems. Unfortunately, with this particular process there is no avoiding the odor and it is just the nature of the beast.

Tub casting on the other hand is completely odorless! The material is classified as 100% solids and contains absolutely no solvents and even has a VOC near 0. This service was definitely designed with the homeowner in mind because it provides maximum comfort through the duration of the service. This no-smell feature is ideal for occupants with allergies and/or asthma, those who are sensitive to smell (i.e. pregnant women, young children, or elderly people), and high-rise apartment complexes. Tub casting allows for the benefits of tub resurfacing without the inconvenient trade-off of muscling through the smell for 24 to 48 hours. Plus, PureCoat is eco-friendly and compliant with most green initiatives.

THICKNESS

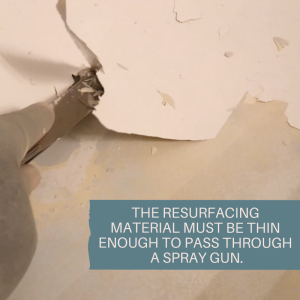

The thickness in material is another huge difference between tub resurfacing and tub casting. Since traditionally resurfaced items are sprayed the coating must be thin enough to pass through a spray gun. So the spray application really limits the level of thickness refinishers are able to achieve with that particular coating. Although, the refinishing coating is much thinner than tub casting coating properly maintained surfaces can last about 10 years before any signs of coating failure.

PureCoat is about five times thicker than traditional resurfacing coatings. With no spray gun to worry about this coating is as thick as it gets! And without the solvents what is applied to the tub stays in the tub. No more evaporating coatings or smelling that gross gassing-off effect that is created during the resurfacing process. Where traditionally resurfaced tubs fail tub casting stands the test of time.

These three fundamental differences between tub resurfacing and tub casting are what really highlight their benefits. While both are under the same umbrella of “tub refurbishment” they are both unique unto themselves. And both service has something different to offer each homeowner depending on their needs. What cannot be denied is that the future of partial bathroom remodels is very bright, thanks in part to tub casting. But rest assured, the other more classic methods will never really go out of style.