The Evolution of Tub Refinishing

Those who don’t understand history are doomed to repeat it. And my friends, I am sorry to say the tub refinishing industry has been on full repeat for 30 years. Unfortunately, in the refinishing world not much has changed since 1989 in terms of process. But let me put that in perspective for you…in 1989 the Berlin Wall was still standing, a gallon of gas was 97 cents, and the first episode of the Simpsons aired on TV.

When you look around it’s not hard to see that so much has changed since then, but apparently not tub refinishing. And before you think it’s due to the “if it’s not broken don’t fix it mentality” let me assure you it’s not. I am sorry to be the bearer of bad news but the refinishing industry has not perfected their process in those 30 years, because we’re still dealing with its numerous pain points: peeling, chipping, flaking, and that awful odor. And if we’re being completely honest the quality has even declined slightly to help drive prices down to a competitive rate. So why has the industry accepted mediocrity as the norm? Well, l’m glad you asked!

Chemical & Mechanical Bonding and Everything In-between

Technically speaking tub refinishing is nothing new. Ever since John Kohler invented the American bathtub in 1883 people have been searching for a service more extensive than cleaning but not as involved as a full replacement to help combat the dinginess associated with a well-loved bathtub. But it wasn’t until the invention of epoxies, urethanes and polymers that helped launch the cosmetic service known today as tub refinishing. But over the last 30 years there hasn’t been much progression, but more importantly there hasn’t been a demand for advancement.

But if we are speaking on progression it is important to discuss bonding. One of the biggest advancements in tub refinishing is bonding, or the method in which the coating bonds to the tub. In the early days of refinishing mechanical bonding was the norm and refinishers had to rely on sheer elbow grease to get the job done, usually by sanding. Years later the use of chemical bonding agents became more common and mechanical bonding became secondary and refinishers tend to just choose one or the other. And although refinishers generally use different methods and techniques to prep and spray but the mantra remains the same: a refinished tub is only as strong as its’ prep work.

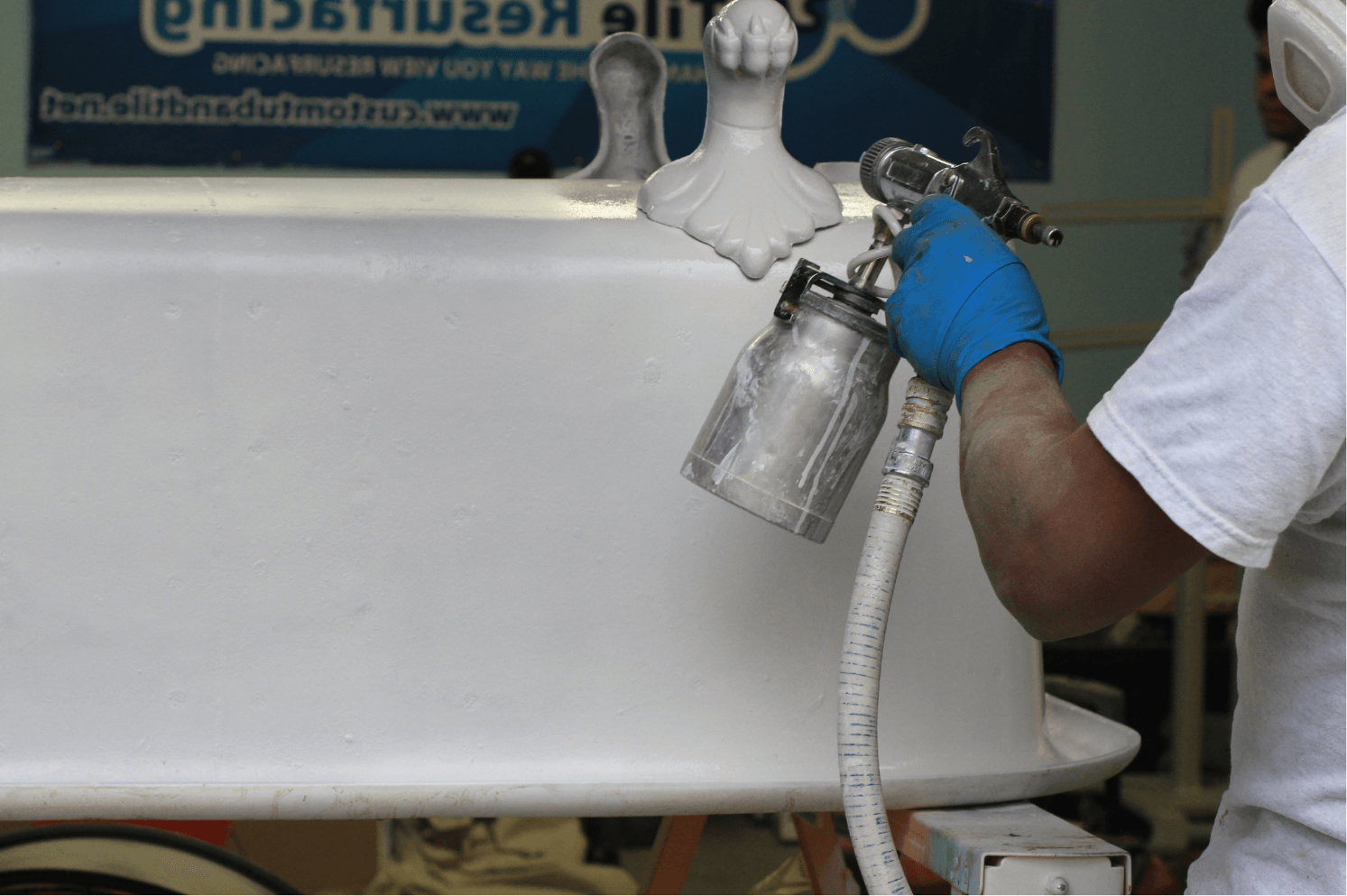

***Custom Tub and Tile Resurfacing uses both chemical and mechanical bonding techniques in their traditional tub resurfacing service.***

Our prep process involves chemical etching by using a liquid acid etch, or chemical bonding. It eats away at the gloss making the tub more porous and a better surface for our coating. As well as mechanical bonding through sanding.

Cutting Ourselves Off At The Knees

The biggest detriment to the quality of work in the tub refinishing industry is other refinishers. In an attempt to keep prices competitive in both the commercial and resident realms refinishers are undercutting each other (and themselves). Quality becomes secondary to quantity and the consumer is ultimately the one who suffers. This practice has become so frequent it is not unusual to see tub resurfacing services offered for under $200. But it is also important to recognize that these tubs are the same ones showing signs of premature coating failure. Now this could be due to two reasons: the first one being a cheap process and a cheap product as mentioned above. The second reason could be the person doing the work.

The biggest detriment to the quality of work in the tub refinishing industry is other refinishers. In an attempt to keep prices competitive in both the commercial and resident realms refinishers are undercutting each other (and themselves). Quality becomes secondary to quantity and the consumer is ultimately the one who suffers. This practice has become so frequent it is not unusual to see tub resurfacing services offered for under $200. But it is also important to recognize that these tubs are the same ones showing signs of premature coating failure. Now this could be due to two reasons: the first one being a cheap process and a cheap product as mentioned above. The second reason could be the person doing the work.

I’ll let you in on a little secret…literally anyone can be a tub refinisher. There are no regulations or certifications needed to open a refinishing business or to do the work. Joe-schmo off the street can pick up a DIY kit from HomeDepot and start spraying tubs. That means without doing your due-diligence you could have an inexperienced refinisher resurfacing your tubs. And no matter how cheap the work it isn’t worth it to resurface the same tubs year after year.

What Does The Future Look Like?

At Custom Tub & Tile we look mediocrity in the face and laugh. We knew there had to be a better way, or at least a less smelly way, right? Turns out we were right. Enter: Tub Casting! And this is the greatest development the industry has seen in 30 years. Equivalent to the moon landing in terms of significance in the refinishing industry, if you will. This unique synthetic porcelain resin is poured onto the tub eliminating any airborne particles. Not only is it odorless but it comes with a 10 yr warranty.

Biology dictates that those who don’t evolve die, and tub refinishing has died a 30 year death. We are the movers and shakers, the disruptors who demanded change and sought it out. Move over paper thin, spray-on coatings. Step aside peeling tubs. Wave goodbye to annoying odors. And au ruivour to second-rate services in the name of profit. Tub casting is here to stay!